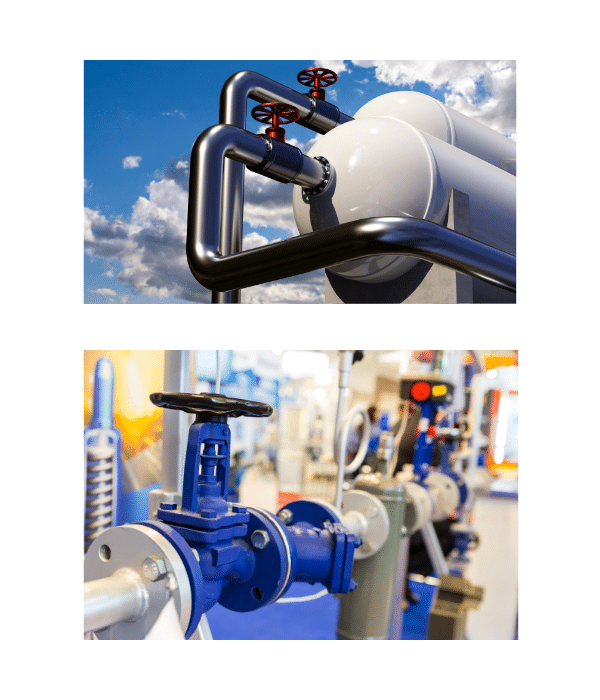

Leading Pump and Valve Manufacturers Depend on Comprehensive Substance Analysis and Complex Calculations to Create Innovative Solutions

Pump and valve manufacturers are faced with multifaceted challenges when choosing the right products to meet their customers' needs. They need to understand the contents and behavior of the components they transport, not just the components themselves. Is it solid, liquid, or gas? Is it acidic, alkaline, or neutral? What is the viscosity, particle size, abrasiveness, and temperature?

In addition, they must also weigh multiple factors to meet customer needs, such as sanitation, installation, delivery, environment, region, cost, maintenance, fluid impact, delivery time, and energy efficiency. For example, what pipes and pumps are needed to transport a high-fat, low-adhesive, high-temperature fluid for a given vertical and horizontal distance?

This example belies the true complexity facing pump and valve manufacturers when they need to propose products to meet their customers' specific needs. The disciplines of chemistry, physics, fluid dynamics and engineering converge to create a challenge unique to this industry.

Seamless Exchange of Data and Calculations Delivers Speed, Scale and Accuracy

Using a Configuration Lifecycle Management solution like Configit Ace®, powered by the multi-patented Virtual Tabulation® technology, pump and valves manufacturers can connect their external databases containing product and material specifications to run calculations that feed back into the user-facing product configurator. Information is seamlessly exchanged and calculated between Configit solutions and the customer’s external databases to produce error-free configurations in real-time and at speed.

In some cases, these external calculations are integrated into a product configuration in the form of an external pump graph tool. This graphical representation of complex calculations includes materials, temperature, specification of pump curves, pump selector and more.

With Virtual Tabulation®, not only can physical components be calculated, but an overlay of additional attributes can be added that identify ideal materials, features and functions based on input of customer’s commercial needs.

Provide Tailored Solutions That Integrate Customer Needs and Exceed Expectations

Using an integrated Configuration Lifecycle Management solution based on Configit’s Virtual Tabulation® technology and Solution Space analysis, pump and valve manufacturers can enable their customers and partners to configure and quote their own solution, speeding up sales processes while reducing the risk of incorrect configurations that could lead to equipment malfunctions or breakdowns.

Because calculations are pre-compiled, users can start the configuration process from any point. For example, they can begin with material being moved, the location conditions, the distance travelled, and more. This means that manufacturers can offer their customers a flexible configurator to design a solution based on their top priorities, including configuration guidance in case of conflicts in choices.

Through integration with external databases, there is no need to duplicate data, and the speed and accuracy of Virtual Tabulation® allows for near instantaneous results of queries with zero errors. Both customer needs and commercial preferences are integrated into one powerful, wholistic solution.

Customer Case: Fisher Emerson - Responding to Dynamic Market Requirements Using an Intelligent, Collaborative Configuration Platform

Challenge

Fisher Emerson, a large, global manufacturing and engineering company providing innovative solutions for customers in industrial, commercial, and residential markets, started a global initiative in 2019 for its Fisher Flow Controls Division to improve response time in speed and accuracy to dynamic market requirements, as well as enhancing collaboration and alignment between Sales and other internal departments.

Solution

With the long-term goal to implement a future-proof Cloud/SaaS solution, Fisher Emerson worked with Configit to develop an intelligent, automated solution that generates initial bid estimates to enable Sales teams to respond faster and more accurately to customer requests.

Benefits

Guided selection that finds the best matched products meeting technical and commercial requirements. Sales can evaluate more options faster. Batch editing of selected products helps revise quotes more quickly. Easy plug-and-play with their existing custom UI application.

Pumps and Valves Companies

Contact us today to schedule your free demo.